3D Printing : What you need to know

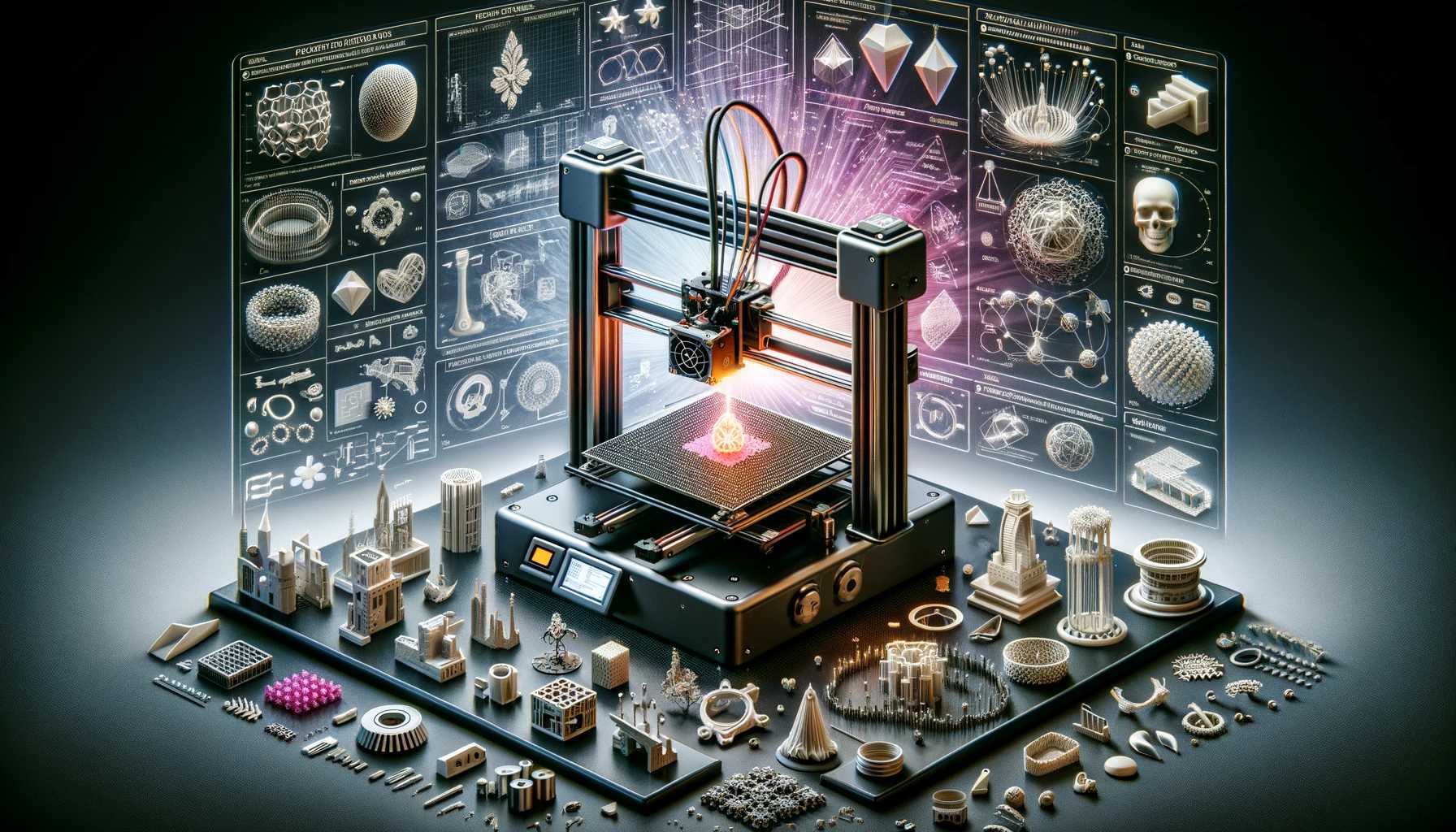

Three-dimension (3D) printing, also called additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. 3D printing or additive manufacturing, is a process where a physical object is created by layering materials based on digital design. The design is sliced into layers, and then each layers is printed by depositing materials (like plastics or metal) one layer at a time.

It’s a bit like building with Lego bricks, but instead of stacking them, the layers are fused together. 3D printing has many applications, from medicine, to fashion to aerospace. There are variety of 3D printing materials, like thermoplastics such as acrylonitrile butadiene styrene (ABS), metals, resins and ceramics.

Types of 3D printing

3D printing is gradually becoming the future of the manufacturing industry. Here is why; there are many processes which are suitable for a different type of materials.

STEREOLITHOGRAPHY (SLA)

This is the first 3D printing innovation in the world, introduced by Chuck Hull in 1986. This is the first modern 3D printing measures. SLA printers dominated by delivering elevated levels of details, tight resistance, and smooth surface completions.

SLA is a quick prototyping measures where accuracy are taken serious. It can create objects from 3D CAD information within an hour.

SLA uses a laser to cure liquid resin. This is the most accurate type and also the slowest. It has gotten support from many great ventures. Part of which are into clinical, aviation, diversion, and also making individual customers items.

FUSED DEPOSITION MODELLING (FDM)

This is the most common and affordable type of 3D printing. It works by melting plastic filament and depositing it layer by layer. This techniques is good for creating large objects, but it’s not as accurate as other methods.

SELECTIVE LASER SINTERING (SLS)

Is more accurate than FDM, and can work with wider range of materials. However, it’s more expensive and has a smaller build area. Nylon-based powders are softened into robust plastic via SLS. Because SLS parts are made from real thermoplastic, they are robust, suitable or practical testing, and able to support snap-fits and living pivots. Parts have rougher surface completions but are more grounded than in SL. Because SLS doesn’t require support structures, it may be used for larger part quantities than other 3D printing techniques.

The entire form stage can be utilized to settle different elements into a single form. Plans that will eventually be infusion-shaped are modeled using a large number of SLS elements.

Examples of 3D printing

- The Strati, which is the first 3D printed car. Strati was created using FDM technology, and it took less than 24hours to print.

- 3D printed houses. These houses are created using a large scale 3D printer, and they can be built in just few day. In some cases the walls of the house are even printed with built-in insulation.

- Researcher has developed a 3D bio-printer that produces organs, tissues, and bones that can be theoretically implanted into human. A printer was used to print artificial skin of any types.

- Overcoming infertility is often a long, painful and expensive process. At the Northwestern University Feinberg School of medicine Chicago, a mouse was implanted with synthetic, printed ovaries. It was proven that the mouse gave birth to healthy babies. This experiment gives hope to the future.

- The speed of manufacturing, design freedom, and ease of design customization makes 3D printing perfectly suited to the robotic industry. Including works to create bespoke exoskeletons and agile robots with improved agility and efficiency.

History of 3D printing

3D printing was the earliest manufacturing equipment developed by Hideo Kodama of the Nagoya Municipal Industrial Research Institute, when he invented two additive methods of fabricating 3D models.

Hideo Kodama’s invention was on laser cured resin rapid prototyping, which was completed in 1981. His invention spread across three decades, with the introduction of sterolithography in 1984. In 1987, the first 3D printer was invented by Chuk Hull, which used the sterolithography process. Other development followed like, selective laser melting, selective laser sintering among others. In 1990-2000s, lots of 3D printers where developed, though very expensive. In 2009, the cost of these dropped drastically dropped to the opening of more users of technology.

Duration of 3D printing

The number of factors determine the duration of printing, like size of the part and the settings used for printing. Also the quality of the finished part is also important when determining the duration of work. Higher quality products take longer time to produce. The quality, size, resolution and quantity of what you are printing determines the duration and speed of production.